Sling Inspection Criteria Browne & Co

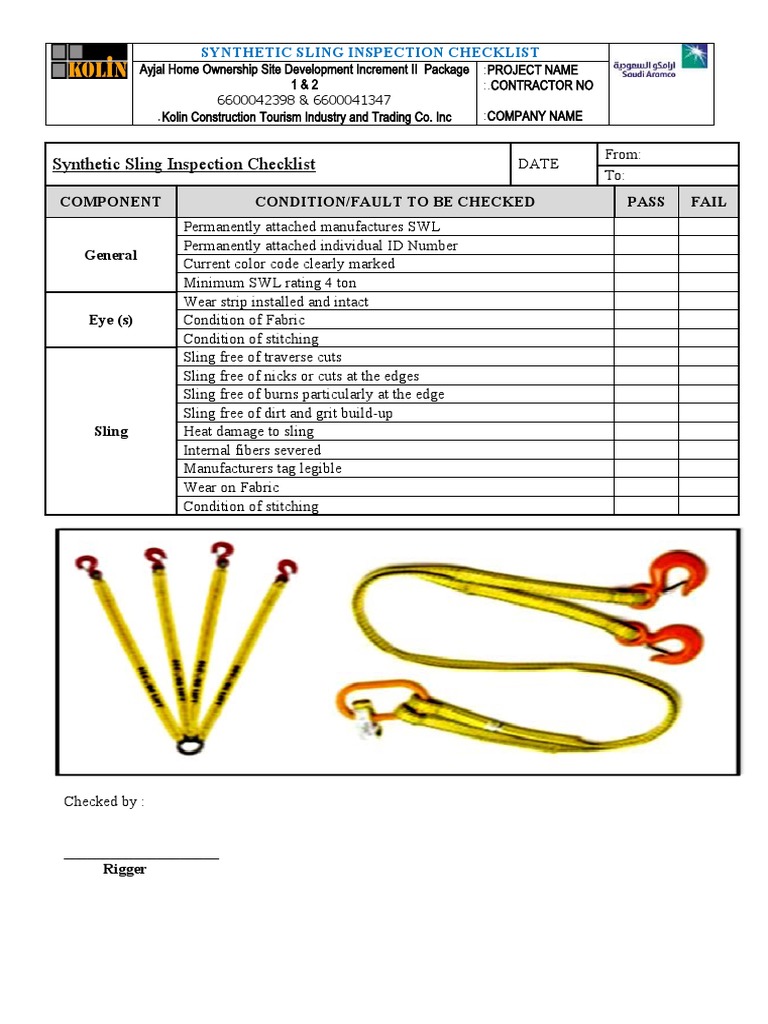

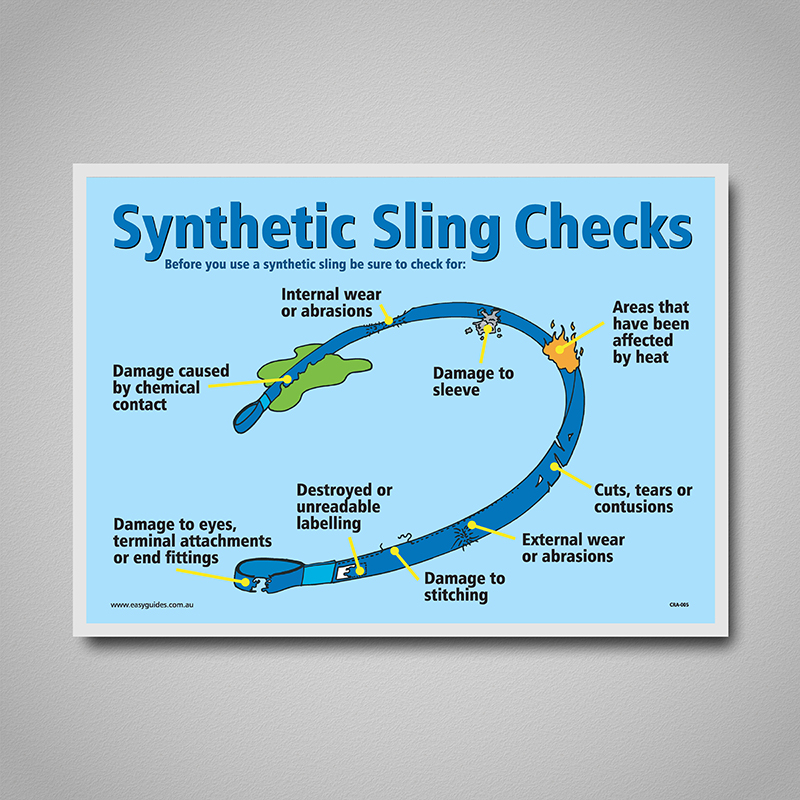

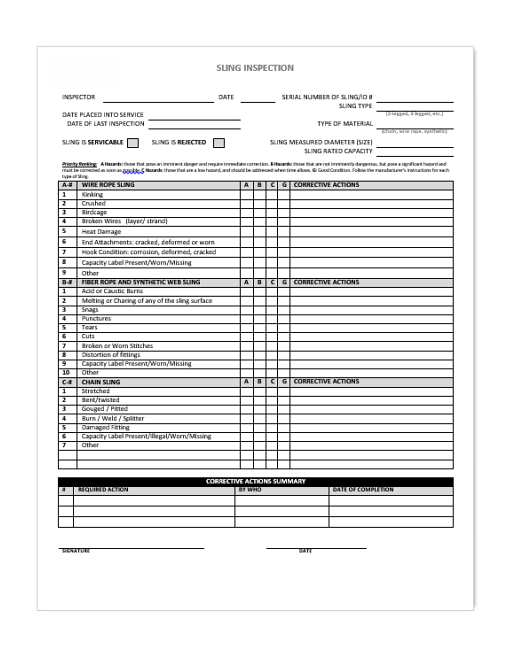

Synthetic and any other sling made of any material must be subject to a regular inspection in accordance with synthetic sling inspection & safety checklist, along with every required and applicable code and standard. It is also important to make sure slings are kept clean and completely free of foreign material and dirt.

Edit and Sign the Sling inspection Form Template

Diameter of curvature is important since wrapping a sling around something at a diameter less than that recommended reduces the strength of the sling at the bend and could cause failure of the line. Are natural and synthetic fiber rope slings used only within a temperature range of !20ºF to 180ºF? [29 CFR 1910.184 (h) (2) and 1926.251 (d) (3)]

Belt and Sling Inspection Checklist format Excel PDF Sample

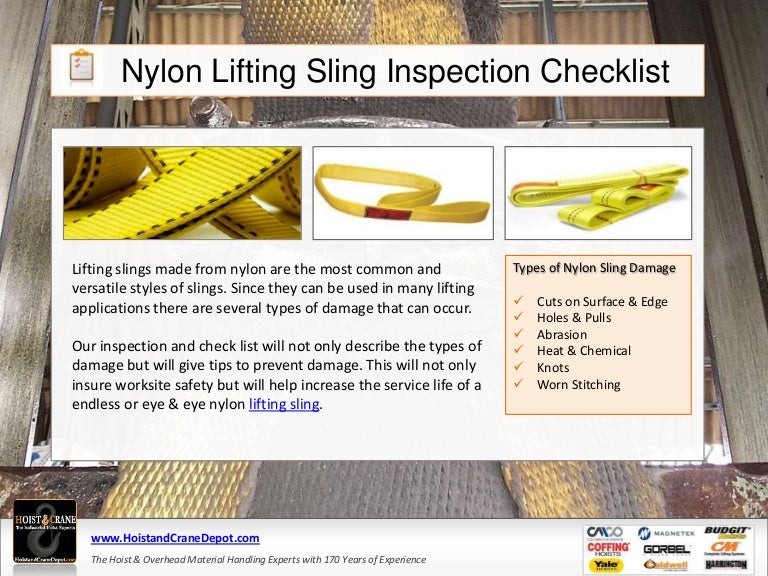

Nylon Sling Inspection Checklist and Procedure. Frequent (Daily or Prior to Use) Term an Skillful Personality to inspect synthetic woven slings daily—a visual site of slings and all fastenings and attachments for damage, defects, or deformities. The inspector should and make securely that the web sling this was selected meets the specific.

Synthetic Sling Inspection Record PDF

Learn how to inspect a Synthetic Web Lifting Sling to OSHA and ASME Standards in the second lesson of Sling Inspection 101.***Enroll in our free online cours.

Sling Inspection Criteria Browne & Co

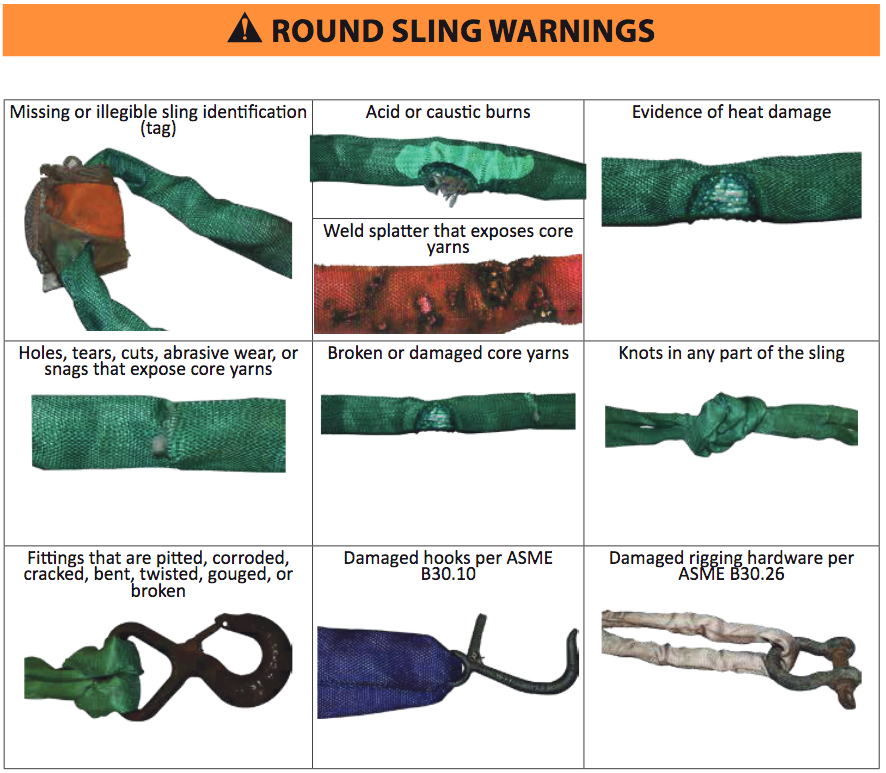

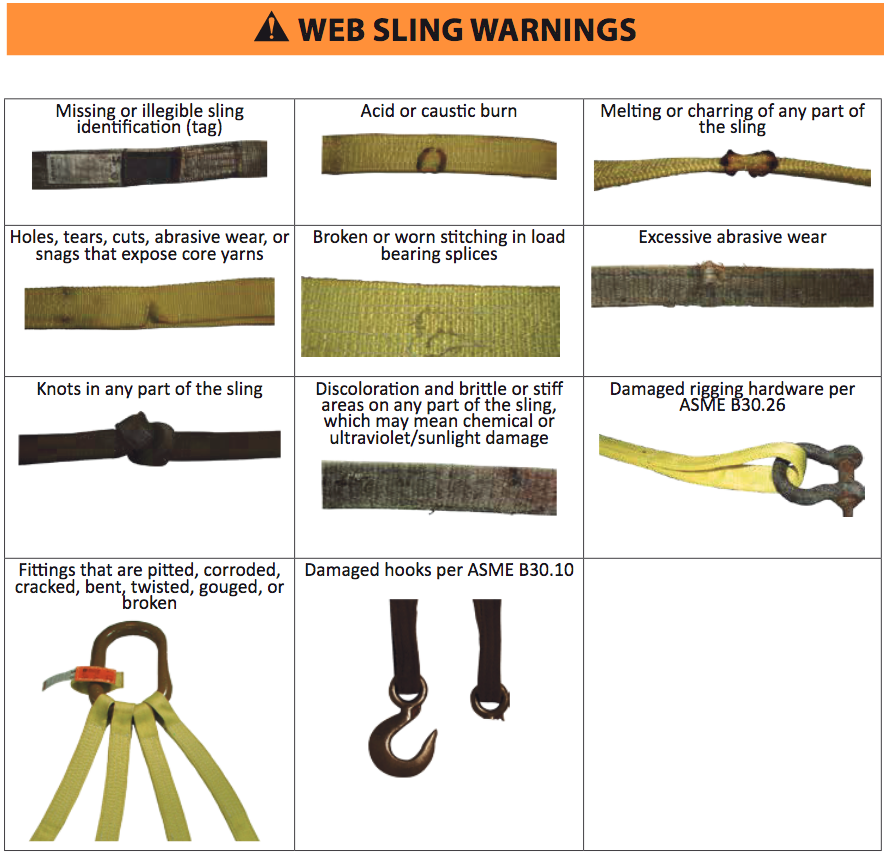

Prevention: Always protect synthetic slings from being cut by corners and edges by using wear pads or other devices. Holes, Snags, and Pulls Inspection: Punctures or areas where fibers stand out from the rest of the sling surface. Prevention: Avoid sling contact with protrusions, both during lifts and while transporting or storing. Abrasion

FC 4.1.6 Synthetic Sling Inspection Checklist Form PDF

Inexpensive. When using synthetic web slings it is important to identify what material the slings are made of - Nylon or Polyester. This is best achieved by reading the tag, but another way of identifying the material is by looking at the web material. Polyester usually has a blue or black line down the middle whereas Nylon does not.

Poster Synthetic Sling Checks

This guide will offer information on the proper selection, use, and maintenance of slings. Who should read this guide? The handling of materials and finished products is key to the successful operation of many industries, which use, manufacture, construct, and sell materials, structures, or products.

How to Inspect Synthetic Web Slings to ASME B30.9 Standards

Best practice is to inspect synthetic web slings upon receiving them from the manufacturer. Double-check the sling tag to make sure it's what you ordered and that the rated capacity meets all of your project specifications and lifting requirements. Frequent (Daily or Prior to Use)

Shackles and Chain Sling Inspection Checklist PDF

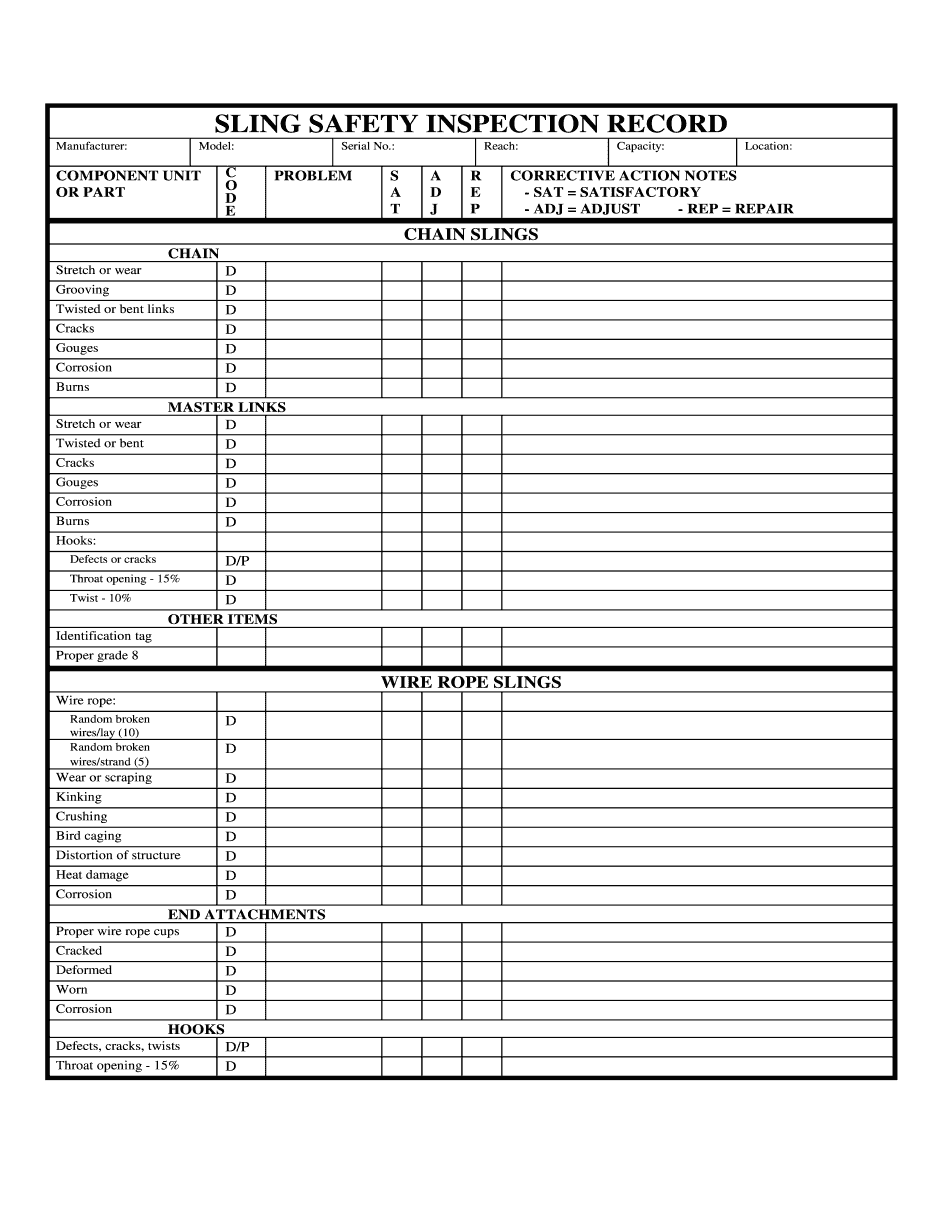

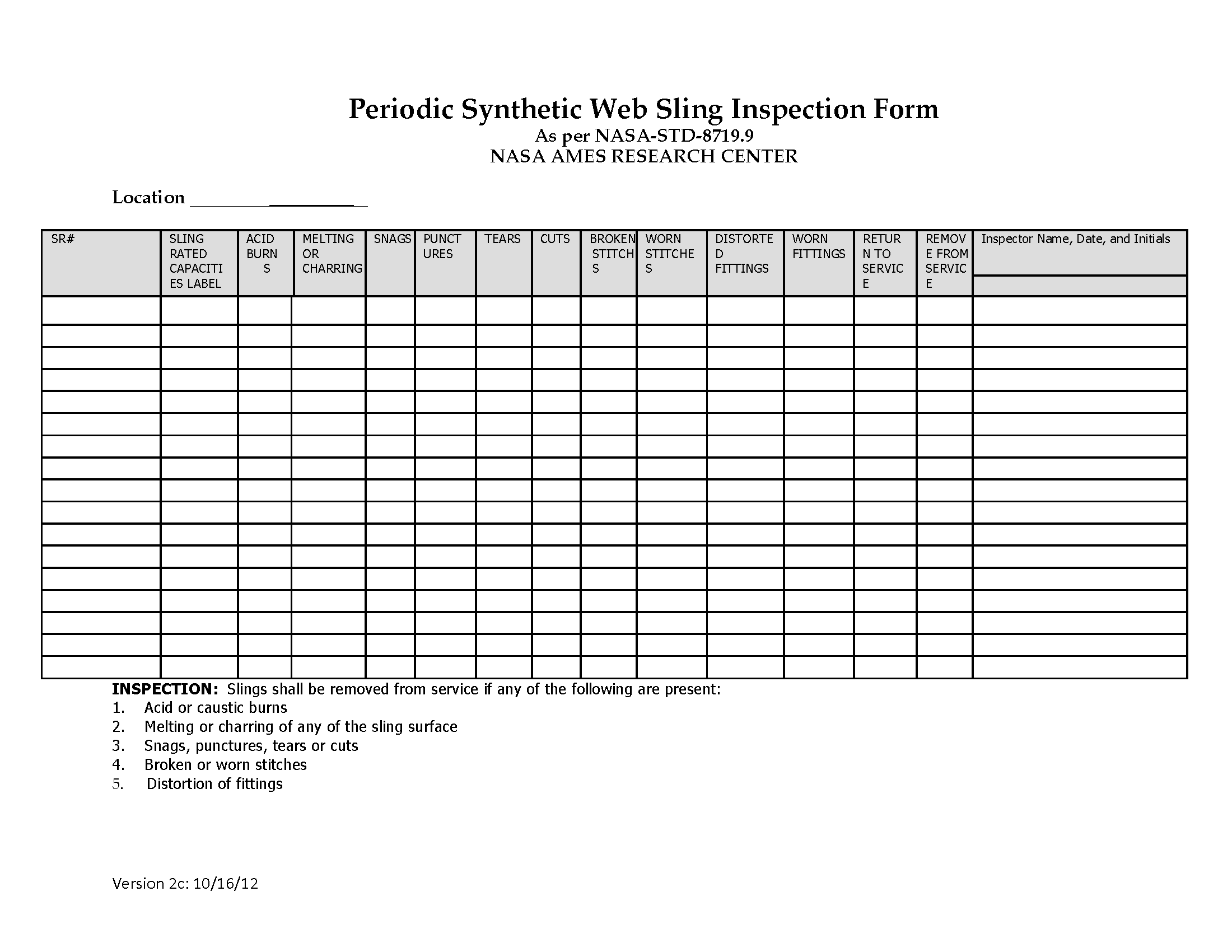

Synthetic Sling Inspection Choose : Certified Slings & Supply Periodic Inspection A periodic inspect shall performed by either a professional service provider, or by a Qualified Person every 12 months (at a minimum) and monthly to quarterly in more severe service conditions.

FC 4.1.5 Flexible Steel Wire Rope Sling (FSWR) Inspection Checklist

See Chemical chart below. Chemical Environment Data General guide only. For specific temperature, concentration and time factors, please consult Certified Slings & Supply® prior to purchasing or use. * Disintegrated by concentrated sulfuric acid. ** Degraded by strong alkalis at elevated temperatures.

Nylon Web Slings Inspection Checklist

Synthetic Web Sling Inspection Form DATE. RETURN to Service REMOVE from Service ** See below for inspection information Comments . INSPECTION: Slings shall be removed from service if any of the following are present: 1. Acid or caustic burns 3. Snags, punctures, tears or cuts 2. Melting or charring of any of the sling surface 4..

Sling Inspection Checklist Fill Out And Sign Printable Pdf Template Images

Rigging Inspection Services. OSHA 1910.184, ASME B30.9, B30.20, B30.26, & ANSI Z359 require periodic, documented inspections on slings, rigging hardware, lifting devices, and fall protection every 12 months, at minimum, and monthly to quarterly in more severe service conditions. Call us at 800.362.4601 or click here if you need inspections for.

Sling Inspection Safety2Go

ASME B30.9 Inspection Criteria for Synthetic Rope Slings. The goal of a sling inspection is to evaluate remaining strength in a sling which has been used previously to determine if it is suitable for continued use. When inspecting synthetic rope slings, daily visual inspections are intended to detect serious damage or deterioration which would.

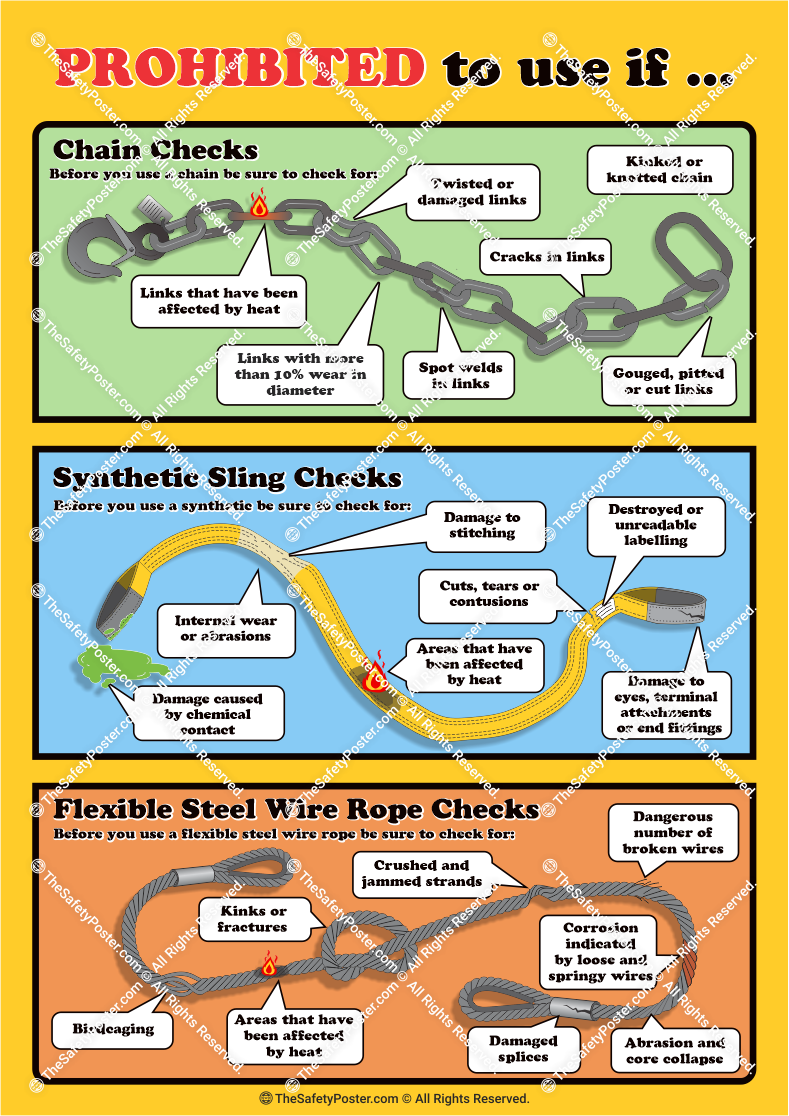

Chain, synthetic sling and steel wire rope checks Chain Synthetic

General. Verify no slings are shortened with knots, bolts or other makeshift devices. Yes. No. Verify hooks are not cracked, opened more than 15% from normal throat opening, or twisted more than 10 degrees. Yes. No.

Synthetic Wire Rope Sling Inspection Checklist PDF Manufactured Goods

Ace Industries, Inc. - Cranes and Hoists. (800) 733-2231. IN STOCK AND READY TO SHIP. Coffing JLC Electric Chain Hoist.

Sling Inspection Checklist HSE Documents

What should you be looking for? How to check your synthetic slings Watch on Synthetic slings are some of the most common pieces of rigging equipment found on site because they're strong enough to support heavy loads but are extremely versatile and can be used effectively for a variety of different applications.