Lime Vertical Shaft Kiln Lime Vertical Shaft Kiln Manufacturers

The main geometry data of the kiln are given in tab. 1 [21, 22]. The main data defining the kiln capacity are as follows: the raw material (dolomite) consumption is 6.7 t/h and the The raw.

100500 Tons Per Day Mini Vertical Shaft Lime Kiln

The FERCALX VERTICAL LIME KILN can be heated either with 100% Blast Furnace Gas or with any other type of Lean Gas, Natural Gas, SynGas, Pulverized Solid Fuel and/or Fuel Oil. Reliability and consistency in the operation and performances are distinctive features.

Lime Production Line Vertical Shaft Rotary Kiln From Chaeng China

The vertical lime kiln is an innovative kiln where the cooling of the lime and the calcination process is completed under positive pressure.

500tpd Vertical Shaft Lime Kiln China Vertical Lime Kiln and Lime Kiln

The main data defin-ing the kiln capacity are: the raw material (dolomite) consumption is 6.7 tones per hour and the sinter dolomite production is 3 tones per hour. The kiln operates in average about 7300 h per year. Heavy oil consumption is about 375-400 L per hours or 125-133 L per ton of sin-tered dolomite.

Refractories for vertical shaft lime kilnrefractory

AGICO has rich experience in the construction of vertical shaft kiln systems and can design and build automatic environment-friendly lime shaft kilns. The company provides turnkey project solutions for the production of active lime. Since 2014, our company has successfully developed TTHN type automatic lime shaft kiln by jointly introducing.

Energy Saving Active Lime Production Line , Vertical Shaft Kiln Small

Shaft kiln, also called vertical shaft kiln or vertical kiln, is a kind of vertical set stationary cement kiln, usually applied in the cement production line, lime production line, etc. As one of the main cement equipment, it plays the same role as a cement rotary kiln for cement clinker manufacturing, also composed of preheating zone.

2017 Yuhong 50200tpd Lime Vertical Shaft Kiln for Lime Production

Vertical Shaft Kiln The Evolution of Vertical Shaft Kiln Technology and its Impact on The Lime Industry February 15, 2023 Lime is used in many different industries and consumer goods, from steelmaking and building to the preparation of food and medicine.

Shaft Kiln Is A Traditional Kiln Type In Vertical Shaft Kiln Shape

Vertical Lime Kiln Plant Learn more TTHN Automatic Lime Shaft Kiln Learn more Why Choose AGICO High quality lime shaft kiln with new technology You can get more useful information about vertical lime kiln. Learn more Advantages of AGICO vertical lime kiln

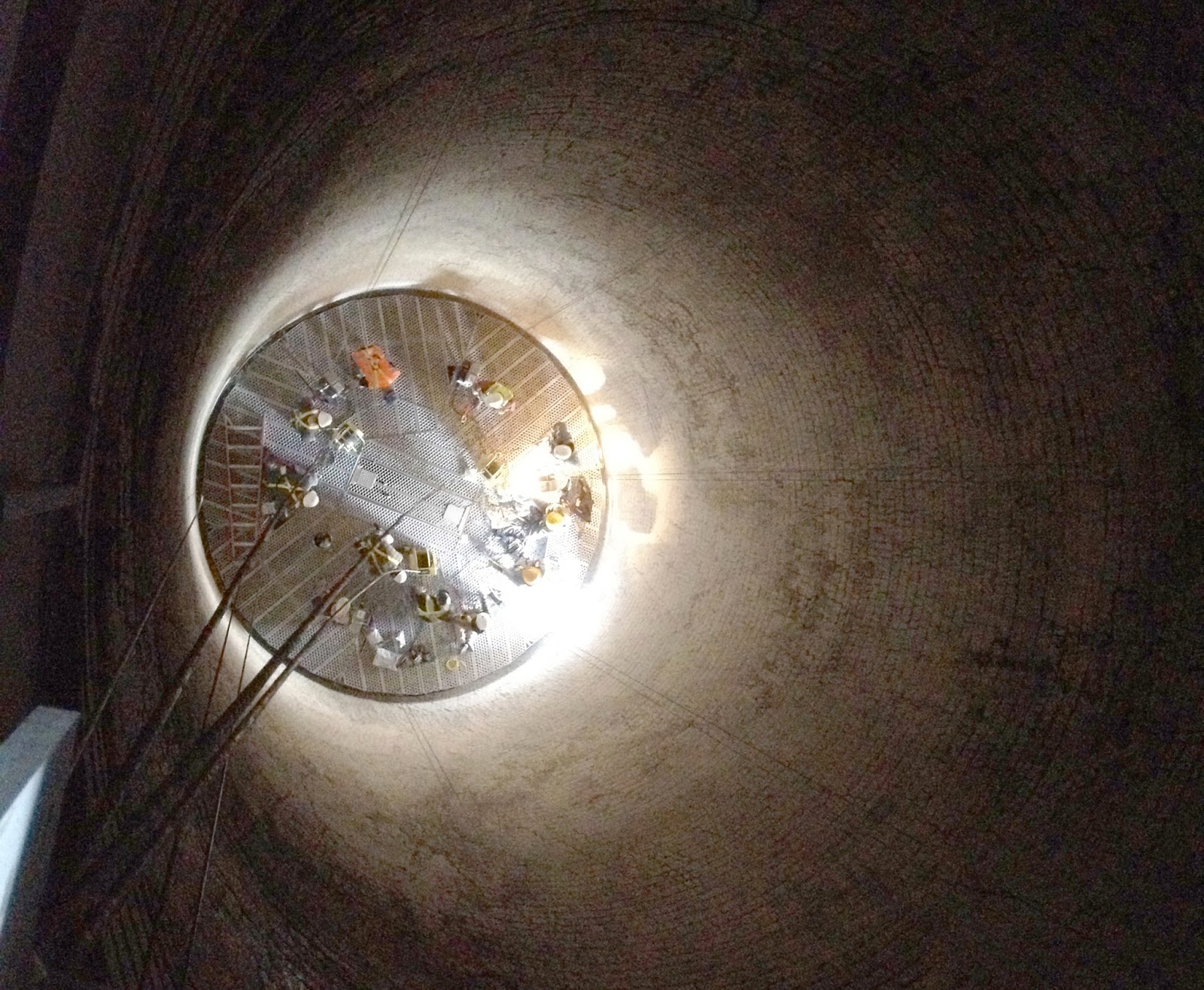

Vertical Lime Kiln Suspended Work Platform — Bricking Solutions

LIME KILNS TECHNOLOGY Experience and a well proven design are the secrets for a successful lime burning project as several factors influence the choice of lime kiln technology: quality of the raw materials, fuel characteristics, specifications of the finished product. Cim-ReVerSy TSR process

vertical kiln/lime/single shaft Handan metallurgica

Lime shaft kilns are stationary vertical kilns where the raw limestone enters at the top and gravity flows through three thermally zoned sections known as the preheating, calcining, and cooling zones.

Vertical Shaft Lime Kiln With 100tpd Buy Vertical Shaft Lime Kiln

open access The annual world lime production amounts to approximately 350 million tons. The most efficient and ecological way to calcine limestone and dolomite is the use of modern shaft kilns.

Bricking Solutions, Inc. Vertical Lime Kiln Utilizes New Suspended

August 28, 2023 600 tpd PFR Kiln with 20% electric energy savings We are happy to inform you about a new order for a state-of-the-art 600 tpd Maerz PFR lime kiln in Tarma, Peru, awarded by the local cement producer… more all News Every year, 300 million tonnes of limestone and dolomite are calcined worldwide.

Switch Common Shaft Kiln To A Environment Protection Lime Vertical Kiln

Vertical Shaft Kilns & Why They Are Diminishing The vertical shaft kiln, or vertical kiln, is a type of calcination equipment used in lime or cement production. It can complete the comprehensive mechanized operation of feeding, calcining, crushing, and discharging.

Pin on Vertical lime kiln for quicklime plant

Easy to control. Daswell vertical shaft kiln for lime is controlled by PLC systems, so that you can monitor the whole calcining process and make easy adjustments. Quality quicklime. It can produce uniform burnt lime with great whiteness. And the vertical kiln production line often works with hydrated lime plant.

600TPD Vertical Shaft Kiln Lime Production Line

The merits of vertical shaft kiln include: Simplicity of construction and operation Low initial cost High thermal efficiency High volumetric efficiency Minimum decrepitation of solid products and minimum erosion of refractory linings due to slight movement of particles relative to each other.

Lime Vertical Shaft Kiln at Rs 5000000/piece Vertical Shaft Kiln in

Twin Shaft Parallel Flow Regenerative Kilns. Twin shaft parallel flow regenerative kilns have two inter-connected, vertical shafts which are fired in sequence to achieve excellent energy efficiency. The stone size used by these kilns is usually between 90mm and 125mm. They are, on the whole, fuelled by natural gas and produce high reactivity.